Solar Photovoltaic Systems: A Guide for Long-Term Ownership and Maintenance

Prepared by Solar One

for the

New York City Department of Housing Preservation and Development

May 2021

Table of Contents

Introduction

Solar PV System Overview

Best Practices for Solar Design and Installation

Best Practices for Solar Project Closeout

Maintenance Issues and Tips

Conclusion

Disclaimer: Solar One staff has made a good faith effort to provide accurate and useful information in this document. Please note that this document is provided on an as-is basis. Solar One and the NYC Department of Housing Preservation and Development make no claims regarding the accuracy of the content provided herein. Building owners installing solar are advised to consult their tax, accounting and engineering professionals regarding their solar project.

Introduction

This guide is intended to serve as a resource for affordable housing developers and professionals to support the construction and maintenance of cost-effective and high-performance solar energy systems. Solar electricity is a mature technology; however, until recently, the cost of this technology was prohibitive for most affordable housing developments. Now, the benefits of solar are widely recognized, and an ever-increasing number of building owners are installing solar to reduce long-term operating costs.

NYC has committed to 1 gigawatt of solar by 2030. Solar on private property is essential to achieving this goal. While Local Laws 92 and 94 of 2019 mandate solar or green roofs on all new roofs, affordable housing is subject to the New York City Department of Housing Preservation and Development’s (HPD) alternative compliance pathway until 2024. HPD’s Solar Where Feasible policy requires solar on affordable housing when it is cost-effective, ensuring that investment in clean energy helps create and preserve affordable housing by lowering building operating expenses, creating green jobs, and reducing harmful emissions. HPD has partnered with the New York State Energy Research and Development Authority (NYSERDA) and non-profit Solar One to create tools to identify and optimize solar projects across HPD’s portfolio, and to provide free technical assistance with HPD’s Solar Feasibility Analysis.

As of October 2020, all HPD projects are required to install solar where it is deemed cost-effective. A Solar Feasibility Analysis is required for all projects certifying through Enterprise Green Communities or LEED. For Preservation projects, a solar screening is part of the Integrated Physical Needs Assessment (IPNA) and scoping process. All solar projects must comply with HPD’s Solar Technical Requirements and use a NYSERDA-approved solar company. Up-to-date information and resources for HPD’s Solar Where Feasible program can be accessed here: https://www1.nyc.gov/site/hpd/services-and-information/solar-where-feasible.page.

Like most energy measures, the true cost-effectiveness of a solar photovoltaic (PV) system depends on long-term system performance. Numerous studies by the National Renewable Energy Laboratory, the New York State Energy Research and Development Authority, and other reputable research institutions demonstrate that solar PV systems installed over the last decade reliably generate electricity as forecasted. While solar PV performance is reliable in aggregate, individual system performance may vary depending on factors such as shading impacts, weather variability, solar technology choices, system design, installation workmanship, manufacturer defects, performance monitoring, and preventative/curative maintenance. This guide provides affordable housing professionals with an introduction to solar PV technology, common PV system performance issues, and strategies to optimize long-term solar PV system performance. This resource will be updated periodically through 2023, and Solar One invites your feedback, comments and questions (affordable@solar1.org).

Solar PV System Overview

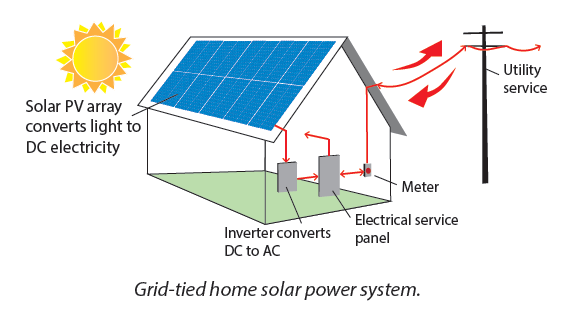

Solar electric systems convert sunlight into electricity, offsetting energy costs and reducing harmful emissions associated with fossil fuel-based electricity generation. Solar electric systems are comprised of solar photovoltaic (PV) modules (a.k.a. solar panels), a mounting system to hold the modules, inverters, and smaller components such as conduit, wires & disconnect switches. Solar PV systems on multifamily buildings are typically grid-interactive, which means the solar PV system and the electric utility both deliver power to the building. Most solar PV systems do not include energy storage/batteries, and cannot provide backup power during a utility blackout. Battery backup will become increasingly common in the coming years as the costs of batteries decline, however it is still relatively rare for multifamily solar projects in New York City. A diagram of a typical solar PV system is shown below:

Image credit: City of Roseville, CA.

Solar PV systems come in many shapes and sizes, ranging from small solar installations on pitched-roof single family homes to ballasted or elevated canopy systems on multifamily buildings or even large ground-mounted solar farms. Solar PV systems provide utility bill savings based on their energy generation over time. Solar energy is measured in kilowatt hours, the same unit of measurement used for calculating electricity bills, but PV systems are typically described by adding up the capacity of each module in watts. For example, a PV system composed of five 350-watt modules would be a 1,750 watt or 1.75 kilowatt (kW-DC) system, while a system using ten of the same modules would be a 3,500 watt or 3.5 kW-DC system.

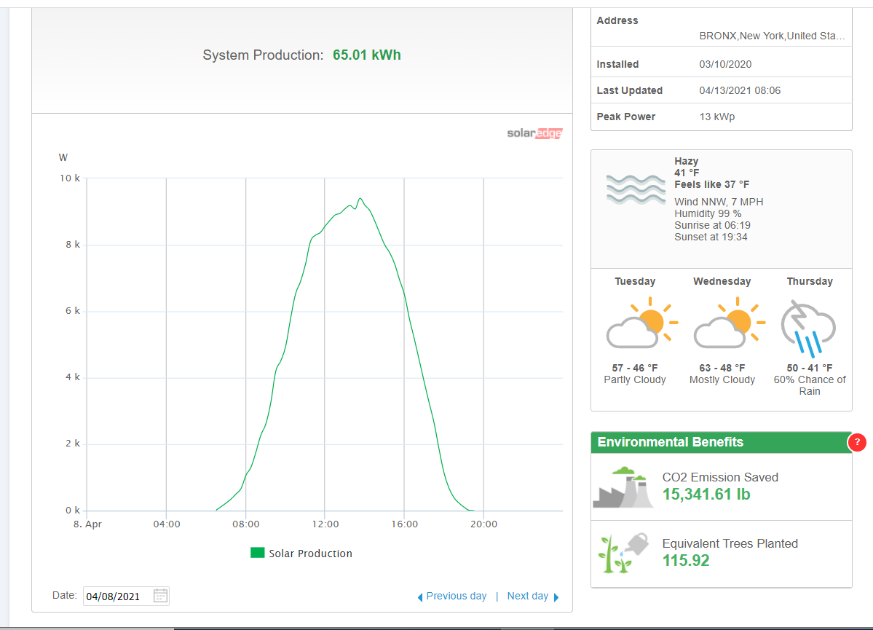

In the northern hemisphere, solar PV systems generate the most electricity per year when they face south or southwest. Solar production is the greatest during the summer months. In New York City, solar PV systems typically generate between 1,000-1,275 kilowatt hours annually per kilowatt-DC of capacity. This metric, known as “solar production factor”, is affected by several variables, including system tilt angle, system orientation, shading, inverter efficiency, downtime for maintenance, and weather variability. Owners and managers of solar PV systems can monitor the performance of their solar PV systems by comparing actual energy generation with forecasted energy generation on a monthly, quarterly or annual basis.

Solar Modules

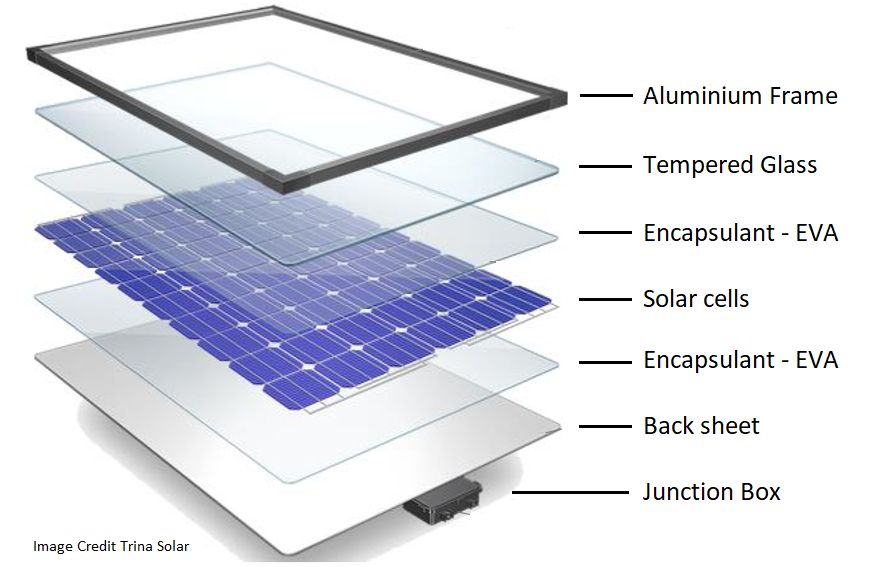

Solar modules, also referred to as solar panels, convert sunlight into DC electricity. The majority of solar modules installed today are crystalline silicon PV modules. A crystalline silicon solar module is typically comprised of 60 or 72 solar PV cells that are connected together in an assembly with an aluminum frame, glass front, encapsulant for the solar cells, a protective back sheet, and a junction box where the power output is routed into wires that can be connected to other solar modules, inverters or power optimizers.

As of 2021, a typical solar PV module has a capacity of 325-425 Watts-DC. The rated capacity of a solar PV module is the maximum amount of power that the module will generate in laboratory conditions. Individual solar PV module are typically 60-80 inches in length, 40 inches wide, and 1-2 inches thick, with a typical weight of ~40 lbs.

Solar modules are designed to reliably produce power for decades with minimal maintenance, and most solar modules carry a 25-year power output warranty. Solar PV module efficiency varies between products. Higher-efficiency modules are commonly selected for NYC projects, even though they generally cost more, because they can produce more power in a given area. Cheaper standard efficiency modules are common but usually installed where space is not a limiting factor. The performance of the solar modules degrades slightly over time due to normal exposure to the elements, typically at a rate of 0.25-0.75% per year. Most solar PV module warranties guarantee that solar PV modules will generate at least 80% of their rated power output at year 25, and many PV module manufacturers have enhanced warranties which guarantee higher performance over time. Solar PV module failure is extremely rare[1], however, factors that can negatively impact PV module performance over time include shading, buildup of dust and dirt, and excessive heat.

Inverters

The inverter is a crucial solar PV system component that converts the direct current (DC) electricity generated by solar modules to alternating current (AC) in order to match the power delivered by the utility so the two systems can interact seamlessly. The inverter is a complex piece of equipment and functions as the brain of the solar PV system. On the AC side, the inverter measures the electric grid voltage and frequency, and modulates the solar PV system output to match the grid. Inverters are designed to shut off the solar PV system immediately in the event of a power outage to protect the safety of utility workers who may be working to restore power.

There are two primary categories of inverters:

| String Inverters | Microinverters |

|

|

|

|

Module-level performance optimization can also be accomplished using DC optimizers with string inverters. DC optimizers are small electronic devices that work in tandem with string inverters to allow each module to operate at peak efficiency, and are typically installed beneath each module or pair of modules.

Note: to maximize the performance of a partially-shaded solar energy system, either use microinverters or DC optimizers.

Bank of String Inverters

Microinverter (photo credit: Solar Power World)

Inverter size ranges widely depending on the technology and application, however, a typical multifamily string inverter is the size of a microwave and weighs 50-150 lbs. Individual inverters or a bank of several inverters can be wall-mounted on the rooftop bulkhead (as pictured above left), mounted onto the roof or PV array itself, or installed in the basement electrical room. Microinverters and optimizers are mounted directly beneath solar panels, either attached to the solar module frame or the mounting system.

Inverters are designed to reliably convert DC power to AC power in indoor or outdoor settings for a decade or more. While power conversion efficiency varies, inverters typically convert DC power to AC power with an efficiency of 96-99%. String inverters typically carry 10-12 year warranties (with optional extensions to 20 years) while microinverters and DC optimizers usually have 25-year warranties.

Mounting Systems

All rooftop solar energy systems have a mounting system to attach the solar PV modules to the building and hold them in place. Solar mounting systems are either mechanically attached, ballasted, or a combination of both. Mechanically attached systems include anchors that mechanically integrate the solar mounting system to the building. For pitched roofs, mechanical attachment is required and aluminum rails elevate the solar panels 2-6” above the roof surface, where they are installed co-planar with the roof. On low slope (“flat”) roofs, light-weight mechanically attached mounting systems can be elevated a few feet above the roof surface to allow for roof access and maintenance underneath the solar arrays. Heavy-duty mechanically attached systems can be elevated 9 feet or more above the roof surface, and are often referred to as solar canopies or pergolas. Solar canopy designs enable developers to maximize solar PV system size and can create useable rooftop space beneath the solar modules.

Mechanically attached mounting system

Elevated solar canopy, mid-installation

Ballasted mounting systems require few or no mechanical attachments, and instead use an engineered tray, concrete blocks, and wind deflector system to fix solar arrays to a rooftop. Ballasted solar arrays are low-profile, and typically fix solar modules 6-24 inches above the roof surface at a 0-10 degree tilt angle. Ballasted mounting systems are popular, especially for solar retrofits on low rise buildings, because they do not require roof penetrations and are typically less expensive than mechanically attached systems. Mounting system considerations are discussed further in later sections of this guide.

Low-profile ballasted mounting system

Performance Monitoring

While performance monitoring is easily overlooked, it is a critical component of solar energy systems and all solar PV systems installed today include performance monitoring capabilities which allow PV system owners and operators to view their solar production online. Solar inverters are capable of measuring, recording and transmitting detailed data regarding system performance, including instantaneous power output, energy generation, AC and DC electrical characteristics, and error codes. Inverters are typically connected to the property’s router via Wi-Fi or an ethernet cable. If onsite internet is not available at a property, cellular monitoring kits can be installed on the inverter or communications gateway to provide the same performance monitoring functionality. It is also possible to monitor the output of a solar energy system with external meters (not integrated with the inverter), and solar performance data can be imported into building management systems (BMS).

Best Practices for Solar Design and Installation

There are several important considerations and best practices that development teams can use to implement successful solar projects.

Contractor Selection

One of the most important decisions that a development team can make to ensure a successful solar project is who they hire to complete their solar project. Solar companies are a bit different from other trades because solar companies typically provide turnkey solar engineering, procurement and construction (EPC) services. However, selecting a solar contractor is not so different from selecting a contractor for any other trade; partner with reputable companies that offers quality products and workmanship, competitive pricing, and professional service. When selecting a solar contractor, one should consider the company’s qualifications, the design and equipment proposed, the contractor’s workmanship warranty, and pricing. All of these factors are important for the long-term success of a solar project.

One important consideration is that only solar companies on NYSERDA’s participating contractor list are able to secure the NY-SUN incentive on the developer’s behalf; a valuable incentive that typically offsets 20-30% of the cost of a solar PV system on affordable housing in New York City. As such, HPD requires development teams for projects that include solar to work with NYSERDA participating contractors. NYSERDA’s participating contractor list can be accessed here https://www.nyserda.ny.gov/All-Programs/Programs/NY-Sun/Solar-for-Your-Home/How-to-Go-Solar/Find-a-contractor/Residential-Installers and HPD’s nonprofit partner Solar One is available from 2021-2023 to provide free procurement assistance for NYC affordable housing solar projects (affordable@solar1.org).

[info_box title=”Recommendations” titleColor=”#fff” titleBgColor=”#5a87f2″ txtColor=”#0c0f0f” txtBgColor=”#e8eefa”]

- Solicit multiple bids from NYSERDA participating contractors with NYC multifamily experience

- Evaluate contractor qualifications, pricing, products, workmanship warranty

- Interview contractors prior to selection and include key development team in the process, such as the owner’s rep, project manager, general contractor, and architect

- Request and check references prior to selection

[/info_box]

Equipment Selection

Quality equipment is critical to the long-term performance of solar PV systems. HPD’s Solar Technical Requirements include HPD’s minimum requirements for solar equipment and contractors. The following sections include more nuanced information for development teams that may be deciding between multiple technologies that meet HPD’s Solar Technical Requirements.

Solar Module Selection

While solar panels may appear interchangeable, there are important differences between solar modules to consider. Solar panel size, efficiency and warranty terms vary. For multifamily buildings in New York City, high-efficiency solar panels with a small physical footprint (60-cell rather than 72-cell) will typically result in a solar energy system that maximizes energy production and utility bill savings.

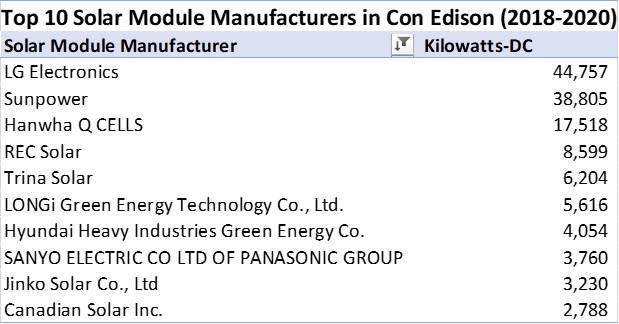

A standard solar panel manufacturer warranty guarantees it will generate at least 80% of its rated capacity after 25 years, while high-efficiency solar modules such as those offered by LG and SunPower guarantee 88-92% output after 25 years. Proponents of premium solar modules will tout the strong warranty as a meaningful benefit, however solar module degradation is typically modest, and failures and warranty claims are rare, so the true value of a stronger warranty may not always justify the higher upfront cost. In addition to considering warranty terms, it is also important to consider the reputation and longevity of the manufacturer who holds the warranty; while SunPower’s power output warranty may be slightly stronger than LG or Hyundai, SunPower only manufactures solar panels while LG Electronics and Hyundai are large, diversified companies.

Source: New York State Energy Research and Development Authority, 2021.

When development teams engage solar companies to request bids for a project, the solar companies will typically complete a preliminary solar design using solar panels that: 1) the company considers appropriate for the application based on site constraints and owner objectives; 2) meet the development team’s technical requirements; and 3) are readily available to the solar company through their warehouse/suppliers at a reasonable price.

[info_box title=”Recommendation” titleColor=”#fff” titleBgColor=”#5a87f2″ txtColor=”#0c0f0f” txtBgColor=”#e8eefa”]

When soliciting bids from solar companies, rather than specifying a particular manufacturer (which could drive up costs), indicate owner preferences and requirements, e.g. “owner seeks to maximize lifetime energy yield with high efficiency solar modules.”

[/info_box]

Inverter Selection

When selecting an inverter for a solar PV system, an important decision is whether to use string inverters, microinverters or string inverters with DC optimizers. If the proposed solar PV system will be partially shaded by trees, chimneys, bulkheads, parapet walls, or adjacent buildings, it is likely beneficial to use microinverters or DC optimizers to minimize shade losses. The table below summarizes the benefits and drawbacks of each option, and ultimately this decision should be made by the owner or the owner’s agent in consultation with the solar company.

| String Inverters | Microinverters | String Inverters with DC Optimizers | |

| Benefits |

|

|

|

| Drawbacks |

|

|

|

| Other considerations | Many products available from reputable companies. Warranty is typically 10-12 years with option to pay extra for extended warranties (typically 20 years). | Limited number of companies offer microinverters. 25 year product warranty is impressive, as long as the manufacturer stays in business. | Limited number of companies offer this product. |

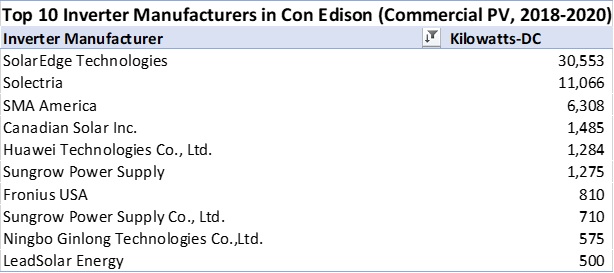

Once a development team has clarity regarding their preferred type of inverter, the next step is selecting a specific solar inverter. When selecting an inverter, it is important to consider efficiency, warranty duration/terms, company reputation, and cost. If a development team procures turnkey solar EPC services then the cost of the inverter itself will not be itemized, however, solar companies can provide alternates and work with development teams to finalize equipment based on owner preference. The table below includes the inverter manufacturers with the most commercial solar market share in Con Edison territory over the last three years. The SolarEdge inverter, which is the market leader, is a string inverter with DC optimizers.

Source: New York State Energy Research and Development Authority, 2021.

[info_box title=”Recommendations” titleColor=”#fff” titleBgColor=”#5a87f2″ txtColor=”#0c0f0f” txtBgColor=”#e8eefa”]

- If the proposed solar array will be partially shaded, utilize microinverters or DC optimizers to maximize energy yield

- Consider purchasing an extended inverter warranty when installing solar; the upfront cost of the extended warranty is relatively modest and it will decrease the likelihood that you will need to pay for an inverter replacement

- During contractor selection, ask the solar company representatives which inverters they recommend and why

- Carefully read inverter warranty and plan for at least one inverter replacement over the life of the system

[/info_box]

Mounting System Selection

Solar mounting system selection is one of the most important decisions regarding solar PV system design. The mounting system selection impacts the building roof as well as the solar PV system. Factors that influence mounting system selection include: local regulations, available roof area, building height, owner preferences, input from the roofer and roofing system manufacturer, and cost. The table below summarizes the benefits and drawbacks of each option for flat roofs. This decision should be made by the owner or the owner’s agent in consultation with the solar company and the roofer.

| Ballasted | Mechanically Attached Planar Array | Elevated Canopy | |

| Benefits |

|

|

|

| Drawbacks |

|

|

|

| Suitability | Ideal for large new roofs (< 5-7 years old) that are less than ten stories in height and which don’t have current or planned uses for the roof. | Small roofs (e.g. rowhomes) that are not suitable for ballasted PV systems are ideal candidates for mechanically attached solar; new construction projects where mechanical attachments can be installed before the roof are also strong candidates. | Narrow roofs (e.g. rowhomes); large, sturdy pre-war buildings; and new construction projects where solar canopies can be integrated into the building’s design and structure. |

| Other considerations | Ballast trays should be placed in a manner that doesn’t impede rooftop drainage. | Roof penetrations and attachments should be completed by a qualified contractor using approved materials. | Zoning evaluation required. Creative engineering may enable projects to integrate canopies with the parapet instead of roof deck. |

[info_box title=”Recommendations” titleColor=”#fff” titleBgColor=”#5a87f2″ txtColor=”#0c0f0f” txtBgColor=”#e8eefa”]

- Notify the roofing manufacturer of planned solar PV system early and solicit their input regarding any design requirements, processes and procedures to maintain roof warranty

- Gather roof warranties/data and share it with solar contractors when requesting proposals

[/info_box]

Best Practices for Solar Project Closeout

This section summarizes actions that you can take as a solar energy system owner to help ensure a smooth project closeout and to help maximize solar performance, incentives and savings.

Physical Completion

Large-scale solar energy system owners often hire a third-party expert to inspect and commission their system. That’s not common for small commercial and multifamily solar projects, but you can confirm that the solar energy system is producing via online monitoring (see below) and there are some common-sense ways that you can confirm that your solar energy system is complete.

[info_box title=”Recommendations” titleColor=”#fff” titleBgColor=”#5a87f2″ txtColor=”#0c0f0f” txtBgColor=”#e8eefa”]

- Request a system walkthrough with the solar company, ideally including your building superintendent, so the solar company can explain how the system works and point out the relevant hardware such as the solar arrays, inverters, conduit, disconnect switches, subpanel and solar breaker.

- Confirm site conditions are acceptable and no tools, building materials, or garbage were left on the roof, in the electrical room, or in rooftop access stairwells.

- Count the solar panels and make sure the number installed match your contract.

- Count the inverters and make sure the number installed match your contract.

- Confirm the make/model of the solar panels and inverters and that the equipment matches your contract.

[/info_box]

Building Inspections and Approvals

Solar installations typically undergo three inspections after they are complete; a Department of Buildings (DOB) electrical inspection, DOB construction inspection, and Con Edison utility inspection. Once the solar energy system passes these inspections, the system can be turned on. NYSERDA also conducts quality assurance inspections of approximately one in every seven solar projects, so there may be a fourth inspection required if your solar project was randomly selected by NYSERDA. Your solar company should inform you when inspections are scheduled and when they are complete. When the solar company indicates that you have passed all necessary inspections, request documentation:

- Final Acceptance Letter from Con Edison

- Letter of Completion from DOB

Please note that scheduling inspections with multiple agencies can be time-consuming, and it can take a few months after construction for inspections to be completed. Be patient with your solar company, but don’t forget to get this documentation.

Roof Warranty

If your building had a roof which was still under warranty and your solar company committed to securing a roof warranty continuance as part of their contract, request evidence from your solar company that your roof warranty is still in effect following the completion of the solar installation. This evidence most typically takes the form of a letter from your roofing manufacturer confirming that the solar installation was completed in an approved method and that their warranty remains in effect. ![]()

Operations & Maintenance

Solar energy systems typically require minimal maintenance once they are installed. However, it’s important to confirm that you have access to your solar monitoring system, understand the terms of your warranties, and that you know the protocol for contacting your solar company for service work.

[info_box title=”Recommendations” titleColor=”#fff” titleBgColor=”#5a87f2″ txtColor=”#0c0f0f” txtBgColor=”#e8eefa”]

- Confirm that you have access to the online monitoring system and that you have credentials to log in and view your solar production. Change the password and store the credentials somewhere safe, and share the credentials with anyone else who may require access. If you are having trouble navigating the online monitoring website, see if you can find free online tutorials from the monitoring/inverter company or reach out to your solar installer for assistance.

- Confirm estimated annual solar energy production by referencing your solar proposal and/or contract. Reference this annual number when you analyze your solar production, but keep in mind that solar production varies seasonally and drops significantly during the winter months.

- Confirm whether your solar company will actively monitor your solar energy system’s performance for the duration of their workmanship warranty. Industry best practice is that the solar installer sets up alerts to notify them if the solar energy system underproduces or detects a malfunction, although some solar companies may charge extra for active monitoring.

- Confirm contact information for your solar company’s customer service/O&M department. Post this information next to the solar inverters for easy reference.

- Request copies of the electrical schematics, owner’s manuals, and equipment spec sheets.

- Request copies of equipment warranties, especially for the solar panels and inverters.

- Confirm that your solar energy system is added to your building’s insurance. Contact your insurance company to inform them that about your solar project, and confirm that the equipment is covered under an existing policy.

[/info_box]

Tax Incentives and Accounting

Solar energy systems in New York City are eligible for federal, state and local tax incentives. In most cases (including the Residential Energy Tax Credit, the Solar Property Tax Abatement, and the Solar Energy System Equipment Credit), the basis for calculating solar tax incentives is the total cost of the system minus the NYSERDA incentive. Note that businesses claiming the Investment Tax Credit have multiple options for how to calculate the solar tax credit basis.

[info_box title=”Recommendations” titleColor=”#fff” titleBgColor=”#5a87f2″ txtColor=”#0c0f0f” txtBgColor=”#e8eefa”]

- Request a paid-in-full invoice when you make your final payment to the solar company. This document can be provided to your accountant for the purpose of claiming tax incentives, and it is can also help reduce risk of disputes with your solar company regarding payment status.

- Confirm that you have the final executed contract on file.

- Speak with your accountant to confirm what documentation they require for the purposes of accounting and income tax incentives.

- NYC Solar Property Tax Abatement: if your solar project was eligible for this incentive, your solar installer should have submitted the application on your behalf during the DOB permitting process. To confirm your property tax abatement amount, reference the PTA4: SOLAR TAX ABATEMENT APPLICATION (FINAL). If you don’t have a copy on file, you can ask your solar company to provide it, or you can also access it via the NYC Department of Buildings’ Building Information System website: http://a810-bisweb.nyc.gov/bisweb/bispi00.jsp or by emailing the DOB at greenroofandsolar@buildings.nyc.gov.

[/info_box]

Maintenance Issues and Tips

Solar PV systems require little maintenance, and performance issues are rare, however issues can arise over a PV system’s 25+ year life. The following section describes some of the more common solar PV system maintenance issues that can arise, along with tips for how to address these issues effectively.

Monitoring Disconnected

One of the most common issues for solar PV systems is that the monitoring system becomes disconnected from the internet. In many cases, this situation is misdiagnosed by system owners as an inverter failure because there is no live or recent power generation data displayed in the online monitoring system. However, just because the monitoring system is disconnected, this does not mean that the solar PV system is off. It is more likely that the building is experiencing a brief internet outage or that the router was reconfigured, replaced, unplugged, or is otherwise malfunctioning.

The cause of monitoring system failure can be as simple as a disconnected ethernet cable

[info_box title=”Tips” titleColor=”#fff” titleBgColor=”#5a87f2″ txtColor=”#0c0f0f” txtBgColor=”#e8eefa”]

Tip: if you receive an alert that a solar monitoring system is disconnected from the internet or you do not see any recent solar production data in your online monitoring system, check other internet-connected services at the property (e.g. security or BMS system) to see if it is simply an internet outage, which is a situation that can be resolved by rebooting the property’s router or contacting the internet service provider.

Tip: If there is not an internet outage, the next step is to call the building superintendent to ask if the ethernet cable was disconnected or if they are aware of any work being done near the solar PV system. It is possible that a contractor completing unrelated work on the roof or in the electric room might have turned off the solar PV system using a disconnect switch, or that they accidentally disconnected the monitoring system.

Tip: If the super is at the property during daylight hours, they can also visually inspect the system and look at the inverters’ LCD display screen and disconnect switches to confirm if the inverters are producing power. If the inverters are not producing power while the switches are in the ON position, this is an indication that there is an actual solar PV system performance issue that may need to be addressed by the solar company.

[/info_box]

Low Energy Yield

If you notice that the solar energy system is generating significantly less energy than forecast or compared to the same period during the previous calendar year, this may be an indication that there is something causing a drop in system performance.

In the event of a real problem with system performance, contact your solar company. During their workmanship warranty period, the solar company will review your online monitoring at no cost, and they may be able to remotely diagnose the issue based on inverter alerts, detailed reports of PV system performance or otherwise. Factors that could cause energy yield to decrease include: shade from tree growth or cellular antenna installation; dust or dirt on solar modules caused by a nearby construction site; microinverter or DC optimizer failure; grid voltage or frequency being out of range and causing the inverter to turn off intermittently; and in rare instances, PV module failure. Some of these issues can be remotely diagnosed by solar professionals while others may require site visits or direct coordination/communication between building staff and the solar company.

[info_box title=”Tips” titleColor=”#fff” titleBgColor=”#5a87f2″ txtColor=”#0c0f0f” txtBgColor=”#e8eefa”]

Tip: if you observe a drop in solar production, first keep in mind that solar production is impacted by weather variability, and will have reduced output during cloudy, rainy and snowy days. Before calling the solar company, check the weather to see if there is a correlation.

Tip: If you believe there is a real system performance issue (e.g. a high-priority inverter error code or a sustained and unexplained drop in production), call or email your solar company to inform them of the issue.

[/info_box]

Inverter Error Codes

Inverters function as the brain of the solar PV system, and when there is an issue, they will transmit an error code via the online monitoring system. These error codes can be incredibly helpful for remotely diagnosing issues, reducing the need for expensive field visits by the solar contractor and/or your building staff. Inverter error codes will alert the system owner and solar installer of issues, such as monitoring disconnection, system outage, DC optimizer failure, grid voltage or frequency out of range, ground faults, or other electrical issues. These error codes can help determine what can be done to address the issue and who is responsible. During the period of a workmanship warranty, the default action to take when there is a performance issue is to contact the original solar installer. Beyond the workmanship warranty period, it may still be appropriate to contact your solar installer to address issues; if a DC optimizer or inverter fails and the product is under warranty, the equipment manufacturer will typically compensate a contractor to repair or replace the faulty equipment, so they may be able to complete the repair at little or no cost to the system owner.

[info_box title=”Recommendations” titleColor=”#fff” titleBgColor=”#5a87f2″ txtColor=”#0c0f0f” txtBgColor=”#e8eefa”]

- Ask your solar installer to provide you with full access to the PV monitoring system and ask them to configure alerts.

- During the final year of your workmanship warranty, contact your solar installer to see if they offer a preventative maintenance plan or service contract; while this may not be a worthwhile investment for a single PV system, for larger solar portfolios it may make sense to pay a third party to monitor and maintain your solar PV system.

[/info_box]

Inverter Failure

String inverters typically come with a 10-12 year manufacturer warranty, and have an expected useful life of 15-20 years. When a string inverter fails, all of the solar PV modules connected to that inverter usually stop generating electricity. The expected useful life of an inverter is shorter than the expected useful life of the solar PV modules, so the owner of a solar PV system should anticipate at least one inverter replacement over the 25-30 year useful life of a solar PV system. When an inverter fails, the online monitoring system will send an email notification to the individuals registered to receive alerts, typically the solar installation company and the system owner. The online monitoring will also show that production has ceased for the failed inverter.

Image credit: Sun Kalp

In the event of an inverter failure, the solar company can typically remotely diagnose the cause of failure using the online monitoring system and work with the inverter manufacturer to get any replacement parts required for the repair. When remote diagnosis is possible, this often enables the solar installer to get a Returned Merchandise Authorization (RMA) from the equipment manufacturer without a site visit; any replacement parts will be shipped to the installer so they can complete the replacement or repair with a single site visit, and then return the defective equipment to the manufacturer in accordance with their warranty. If the inverter is still under warranty, the manufacturer will typically reimburse the installer for labor, shipping and provide a new or refurbished inverter.

Impact and Cost of Inverter Failure

When an inverter fails, this will significantly impact solar energy production and utility bill savings. The financial losses associated with downtime vary depending on the number of solar modules connected to the inverter that is offline, the duration of the outage, and also the time of year. System downtime in the winter will not impact electricity production as much as summer downtime. To calculate the financial impact of inverter downtime, multiply the whole system’s estimated solar energy generation by the percentage of the system that is offline during the downtime by the avoided cost of purchasing electricity.

[info_box title=”Inverter Downtime: Example Financial Impact” titleColor=”#fff” titleBgColor=”#5a87f2″ txtColor=”#0c0f0f” txtBgColor=”#e8eefa”]

System size: 42 kW-DC

Inverter count: 3

Estimated annual solar production: 50,000 kilowatt hours

Estimated annual utility bill savings: 50,000 kilowatt hours x $0.11/kWh = $5,500

If one inverter powering 1/3 of the system is offline for repair during the month of March (an average solar production month), the estimated financial impact on utility bill savings would be ($5,500/12) * (1/3) = $152.78.

[/info_box]

If the same system had microinverters, the financial impact of a single inverter being offline for a month would be significantly less because the failure would only impact one or two solar modules. This is a significant benefit, however microinverter systems have more inverters that could fail at any given time, and because the impact of microinverter downtime is modest, many owners and solar companies will let microinverter failures go for weeks or even months before they address the issue. The same is true for DC optimizers.

[info_box title=”Recommendations” titleColor=”#fff” titleBgColor=”#5a87f2″ txtColor=”#0c0f0f” txtBgColor=”#e8eefa”]

- Configure monitoring alerts that notify a point person at your company when an inverter fails.

- If and when an inverter fails, contact the solar installer for assistance working with the manufacturer to get any necessary replacement parts and complete the repair. Even if the project is no longer under workmanship warranty, contacting your original solar installer for repairs is a best practice, as they will be familiar with the system.

- Like many electronics, if an inverter is faulty, it will usually become apparent in the first year or two. After that, there is a low likelihood of inverter failure until the end of its life – usually 15+ years. Monitor the system most carefully during the first year.

[/info_box]

Module Failure and Vandalism

Solar PV module failure is quite rare, and defective solar modules are normally detected by solar companies during/prior to installation (best practice is for solar installers to test modules prior to installation). However, over the life of a PV system, a module could fail due to either manufacturing defects, accidental damage or vandalism. For solar PV installed on multifamily properties, vandalism and theft are common concerns raised by building owners, however reported incidents of solar vandalism and theft are rare (theft is rare because solar modules are cumbersome and there is no real secondary market for used solar modules). There are several easy measures that building owners can implement to mitigate risk of module damage/vandalism, and system damage can often be detected with the online monitoring system. If a solar energy system has microinverters or DC optimizers, owners and their professionals will be able to detect an individual solar module failure using the online monitoring system. Otherwise, they may simply notice a dip in solar production, or building staff may visually observe damage to solar modules.

Impact and Cost of Module Failure

If a solar PV module fails and needs to be replaced, there is a modest utility bill impact as well as the cost of module replacement. If the solar PV module is defective and needs to be replaced, this is typically identified during the PV system’s first year of operation, and the replacement would be covered by the manufacturer and installer warranties and would be completed at no cost to the building owner. If a solar PV module fails due to accidental damage or vandalism, this would not be covered by the manufacturer or installer warranty and repairs would be an expense for the building owner or insurer. As of 2021, solar PV module costs are approximately $0.30/Watt-DC when purchased in bulk and can be as high as $0.70/Watt-DC when purchased in small volume and for premium brands. Assuming a module cost of $0.40/Watt-DC, purchasing a replacement 340 Watt-DC solar panel would cost $136, and solar module costs are expected to continue to declining over time. There is a labor cost associated with replacing modules that are not covered by warranty, however replacing a faulty solar PV module is typically a quick job and the total cost of replacing two damaged solar modules is likely in the range of $500.

[info_box title=”Recommendations” titleColor=”#fff” titleBgColor=”#5a87f2″ txtColor=”#0c0f0f” txtBgColor=”#e8eefa”]

- Unless your roof contains tenant-accessible recreation space, ensure that roof access is restricted to building staff and contractors by installing and maintaining rooftop door alarms. This is standard practice in New York City multifamily buildings, and reduces the risk of vandalism or accidental damage to a solar PV system. It is also an important measure to protect tenants from injury and to limit the owner’s liability.

- Set up alerts on your online monitoring system and have a designated point person to receive these alerts so you can notify your solar contractor and onsite building staff. Quick diagnosis of issues can minimize downtime/solar production losses.

- Consider asking your onsite building staff to conduct occasional visual inspections of the solar PV system to identify any evidence of physical damage, soiling or other easily identifiable issues.

[/info_box]

Roof Maintenance and Replacement

Solar installations can affect a building’s roof maintenance plan and the costs associated. Best practice is to install a solar PV system on a new or recently repaired roof so major roof work is not anticipated for many years after the solar PV system is installed. However, over a solar PV system’s 25+ year operating life, a building owner should expect to complete significant roof work at least once along with occasional smaller repairs and standard maintenance. Many mechanically attached solar PV systems are elevated several feet above the roof surface or more, which allows for ongoing roof maintenance and repairs underneath the solar arrays. With mechanically attached PV systems, focus areas for maintenance include the points of mechanical attachment.

Low-profile ballasted PV systems are mounted on ballast trays that sit directly on the roof surface. While solar PV systems can protect the roof underneath the array by limiting UV light exposure and protecting the surface from accidental damage/wear and tear from foot traffic, they also make it difficult to access those areas for any required maintenance. Following best practices for PV system installation (such as following roofing manufacturer specifications) and roof maintenance (such as ensuring drains are operable and flashing/sealant is maintained) can limit the need for major roof repairs and extend the useful life of the roof to align with the life of your solar PV system. However, in the event that roof repairs or replacement are required for roof sections underneath a ballasted solar PV system, sections of the solar energy system may need to be removed, temporarily stored, and reinstalled following roof work.

[info_box title=”Recommendations” titleColor=”#fff” titleBgColor=”#5a87f2″ txtColor=”#0c0f0f” txtBgColor=”#e8eefa”]

- Install solar on roofs that are new and/or well-maintained and in good condition. Ensure your building staff complete regular roof inspection and maintenance, particularly around roof drains and flashing.

- Contact your roofing system manufacturer prior to solar installation to ensure that the solar PV installation method is acceptable and will not void your roof warranty. Ensure that your solar company following all roofing manufacturer requirements, which may include using their approved products or contractors to flash any roof penetrations or placing protective mats or sacrificial roofing material beneath ballast trays.

- If appropriate for the roofing system, consider applying a layer of elastomeric coating or a similar product to provide additional protection and extend the roof life before solar installation.

- For low-profile solar PV systems, plan for the removal and reinstallation of the solar PV system as part of future roof replacement projects. Consider requesting an estimated price from your solar contractor for planning purposes. Please note that this expense will vary based on the installer performing the work, the type of system, the size of the system, and the year in which the work is performed. The primary cost of solar PV system removal and reinstallation is the labor, however some wires and fasteners may need to be replaced as part of the system reinstallation. Even if your solar PV system is no longer under a workmanship warranty with the original installer, a qualified solar company should complete the system removal and reinstallation.

- System removal and reinstallation costs can be reduced significantly by completing the work in sections and storing solar equipment on the roof.

[/info_box]

Conclusion

Solar PV systems reliably generate electricity for 25 years, providing utility bill savings and emissions reduction while requiring minimal maintenance and ongoing operating expense. While performance and maintenance issues can arise, building owners and operators can implement best practices from initial system design through construction and operation to ensure that their solar PV perform optimally, maximizing utility bill savings and minimizing operating expenses.

- A 2017 study conducted by researchers from the National Renewable Energy Laboratory observed solar PV module failure rates of 0.05% per year across 54,500 solar PV systems installed and operational between 2000-2015. https://www.nrel.gov/news/program/2017/failures-pv-panels-degradation.html. ↑